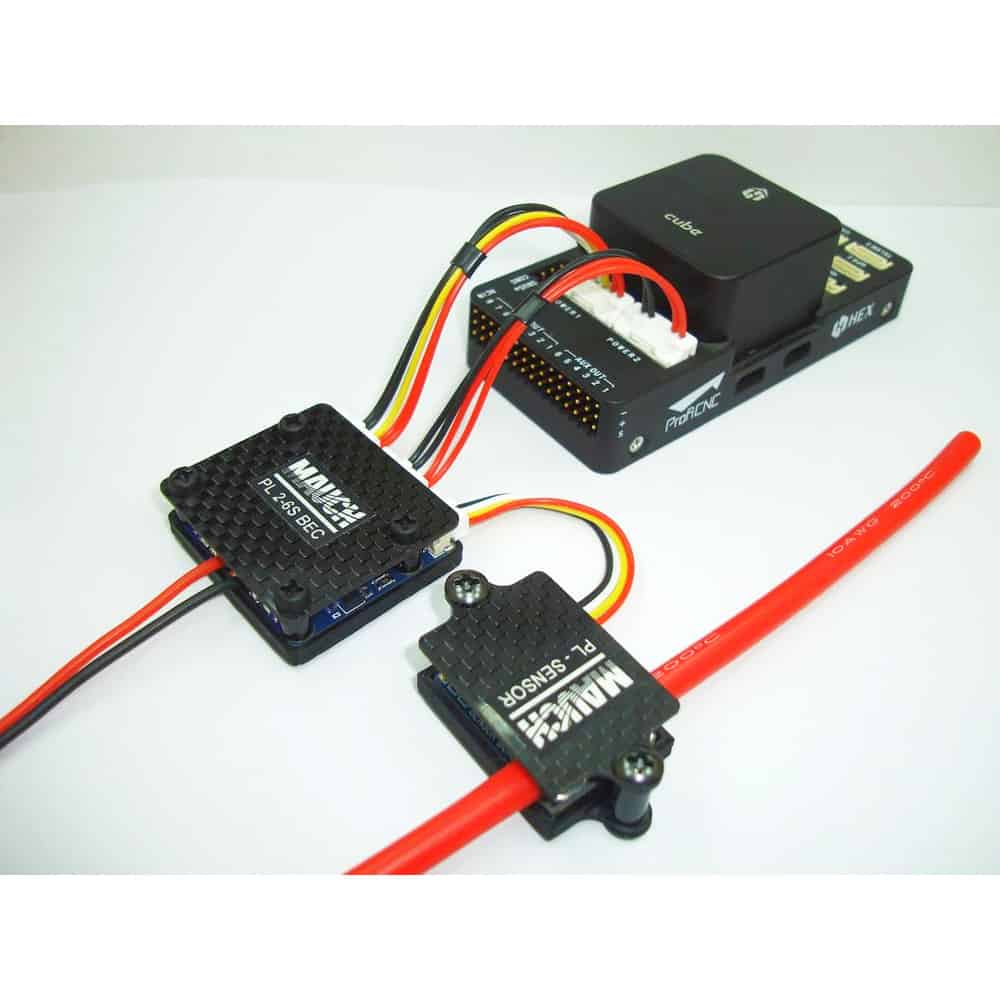

Mauch Premium Line Single Battery Kit

From: $79.09

This complete kit provides all the components and cables necessary to power your flight controller and other onboard equipment.

What’s included:

- 1x Sensor board: 50A, 100A, 200A, or 250A PL current and voltage sensor

- 1x Power supply: PL BEC or HYB-BEC with 1, 2, 3, or 4 outputs

- 1x Power cable (default: Pixhawk 2.1)

Please select the cable matching your flight controller